DeflectoZ

3D Camera for Glass & Metallic Surfaces

Discover DeflectoZ

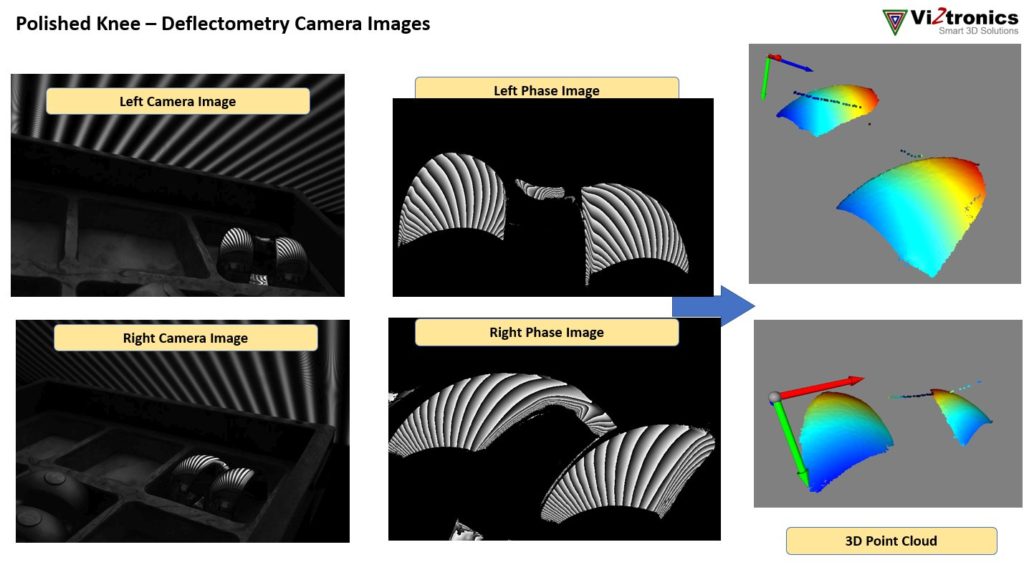

DeflectoZ Multiview Deflectometry

DeflectoZ provides 100% 3D inspection for glass & metal:

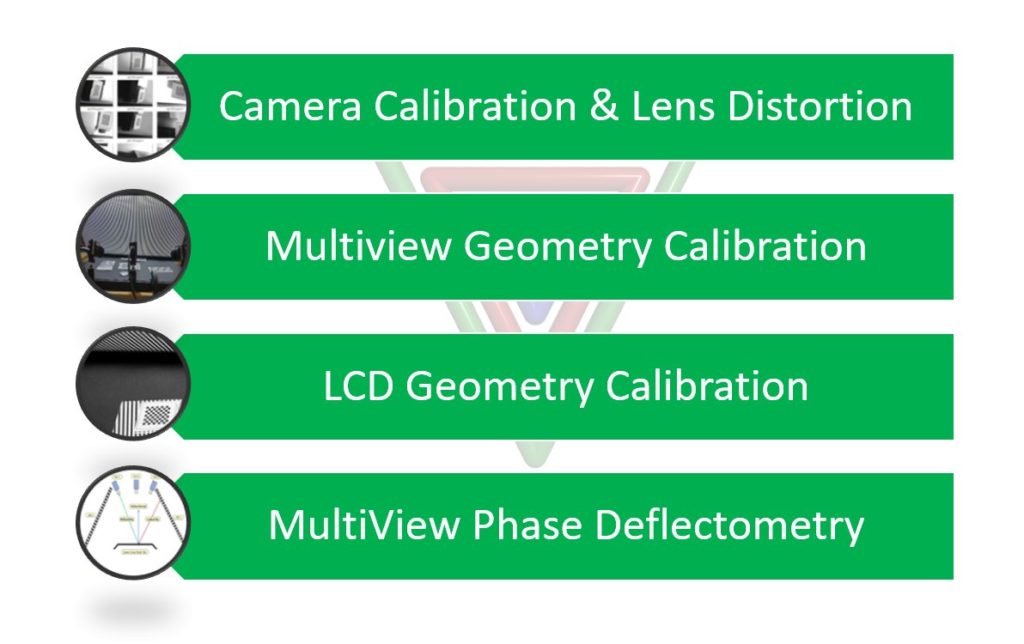

Processing Steps for Deflectometry

DeflectoZ Process Flow

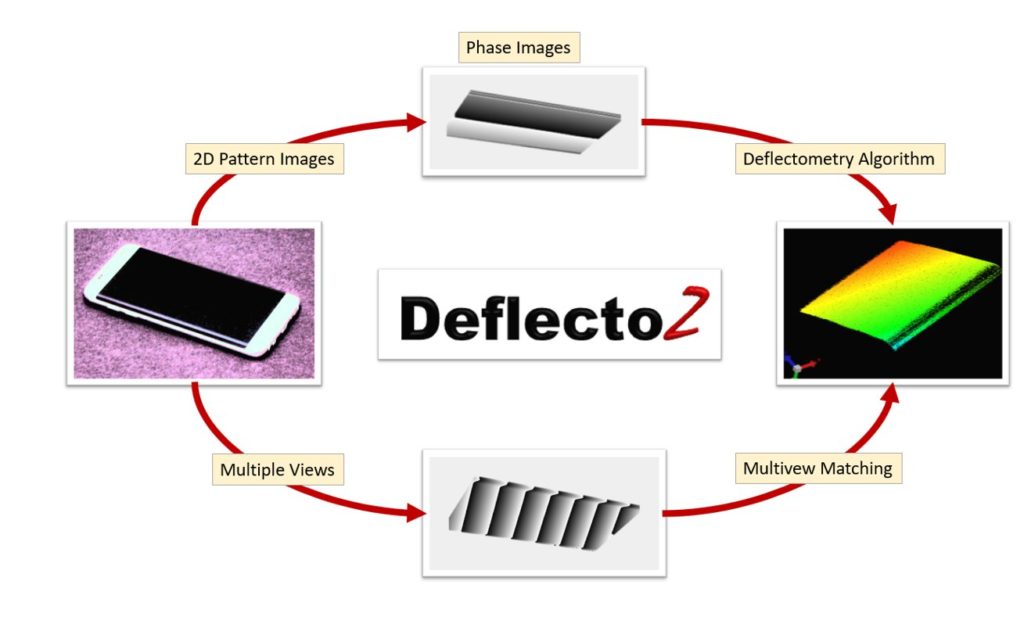

Following diagram shows DeflectoZ processing flow from 2D to 3D:

DeflectoZ Applications

Following diagram shows DeflectoZ processing flow from 2D to 3D:

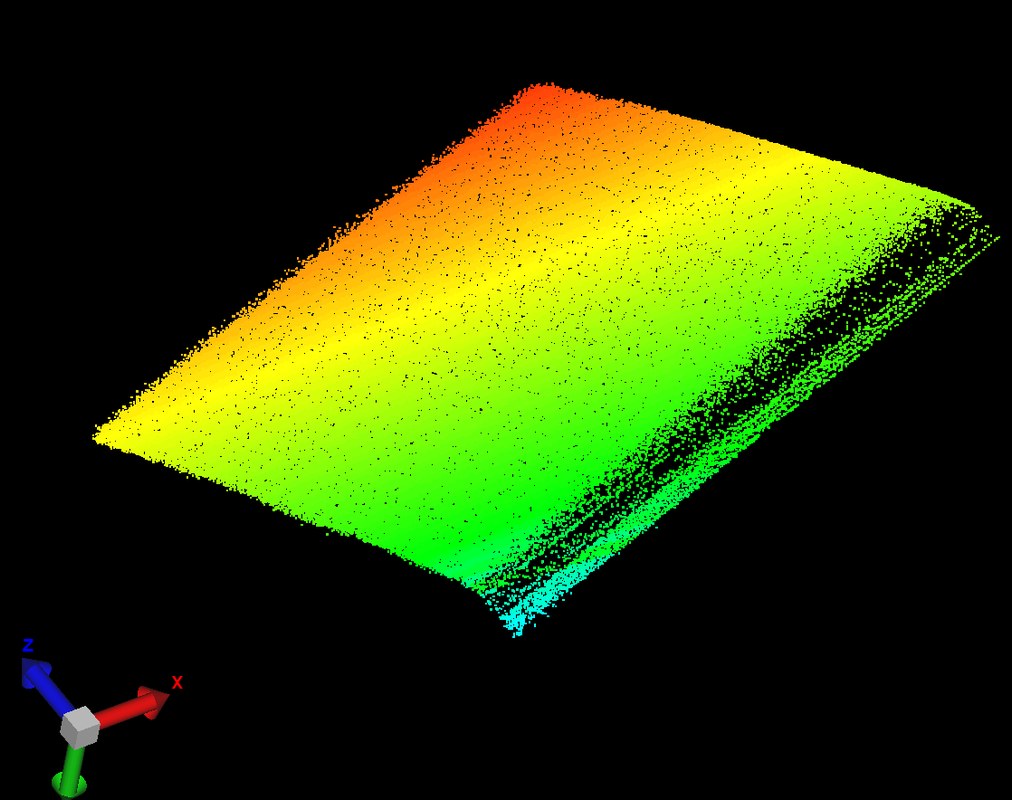

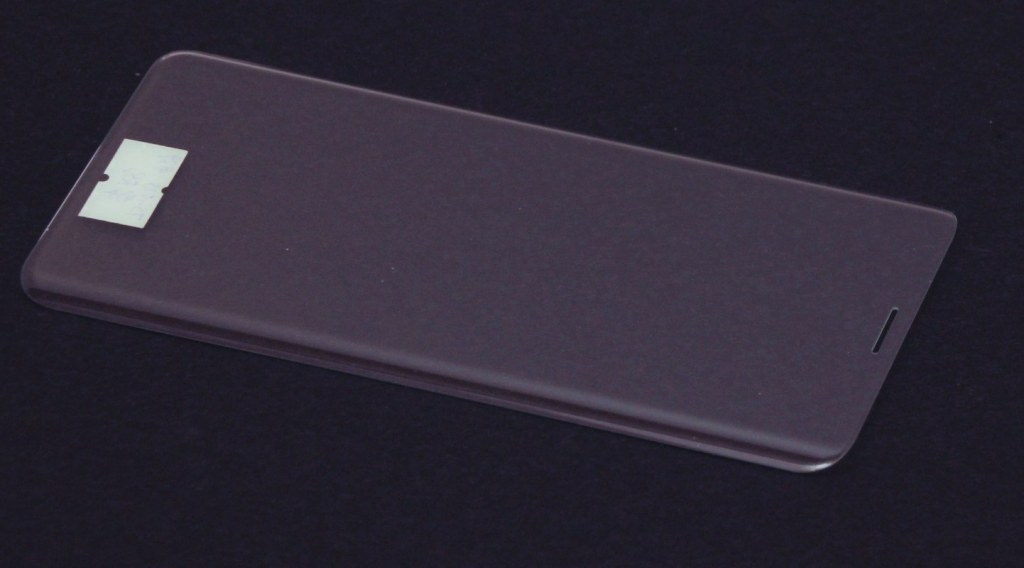

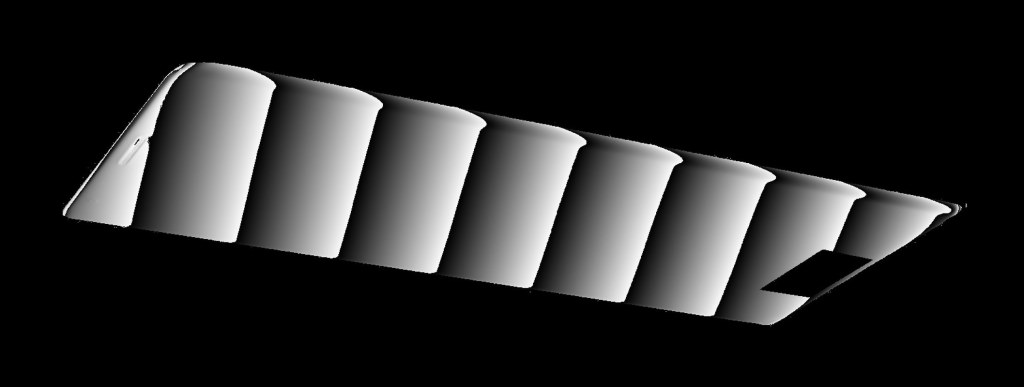

Mobile Screen 3D Inspection

Glass screen covers are a critical component of modern smart phones. Introduction of beveled edges and rounded corners make their quality control even more important. The covers are made from toughened glass which is transparent. The inspection needs high quality 3D data at line speeds. Laser scanning is not an option as it does not work with transparent surfaces. Traditional 3D imaging technologies like CMMs can measure glass but are very expensive and too slow to meet production line speeds and high volumes.

As glass reflects light at a certain angle, Phase Shift Deflectometry (PSD) traditionally used for mirror can be used for measuring 3D surface normals and position for glass. DeflectoZ uses cutting edge deflectometry to inspect mobile screen glass. Multiple cameras allow DeflectoZ to cover sharp edges and curves. Multiview image analysis also removes the ambiguity between surface normal and position inherent to deflectometry.

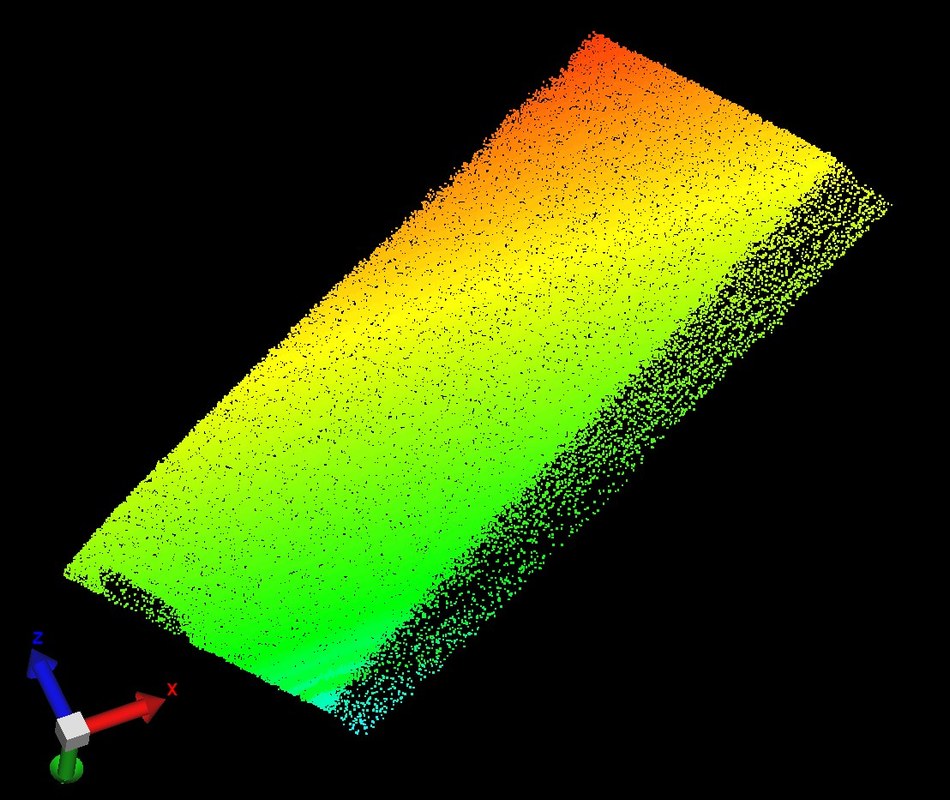

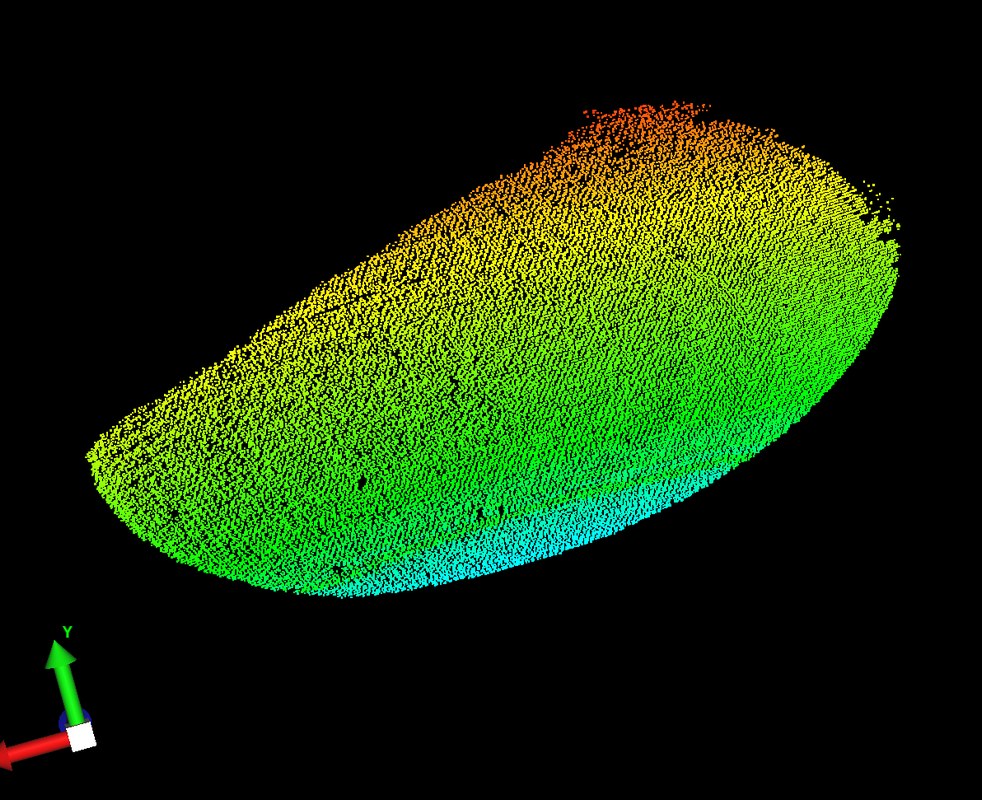

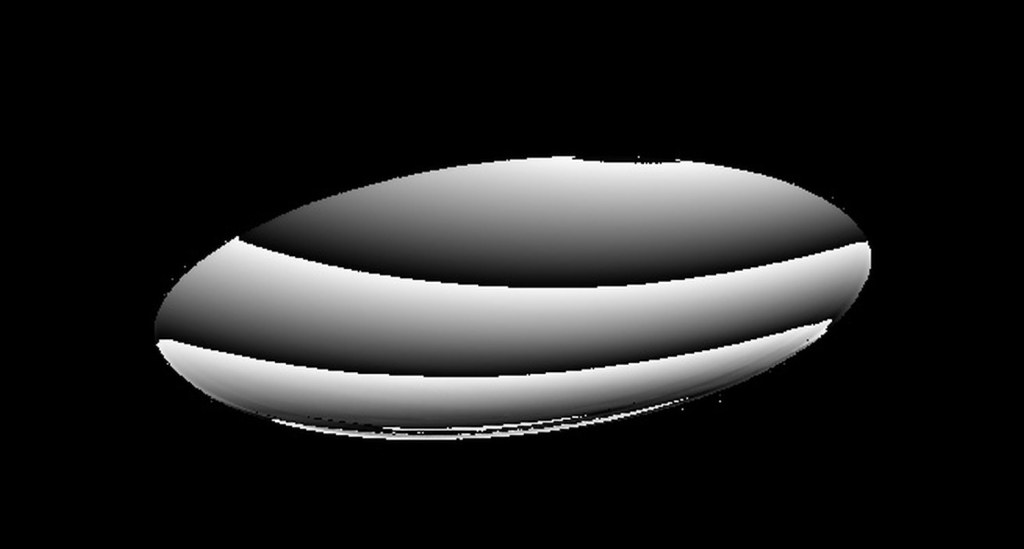

DeflectoZ Results on Samsung Galaxy Phone Screen

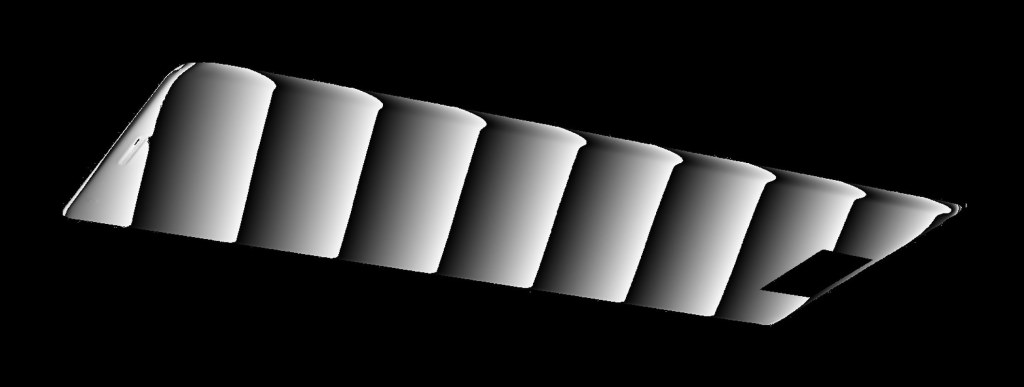

DeflectoZ Results on Huawei Phone Screen

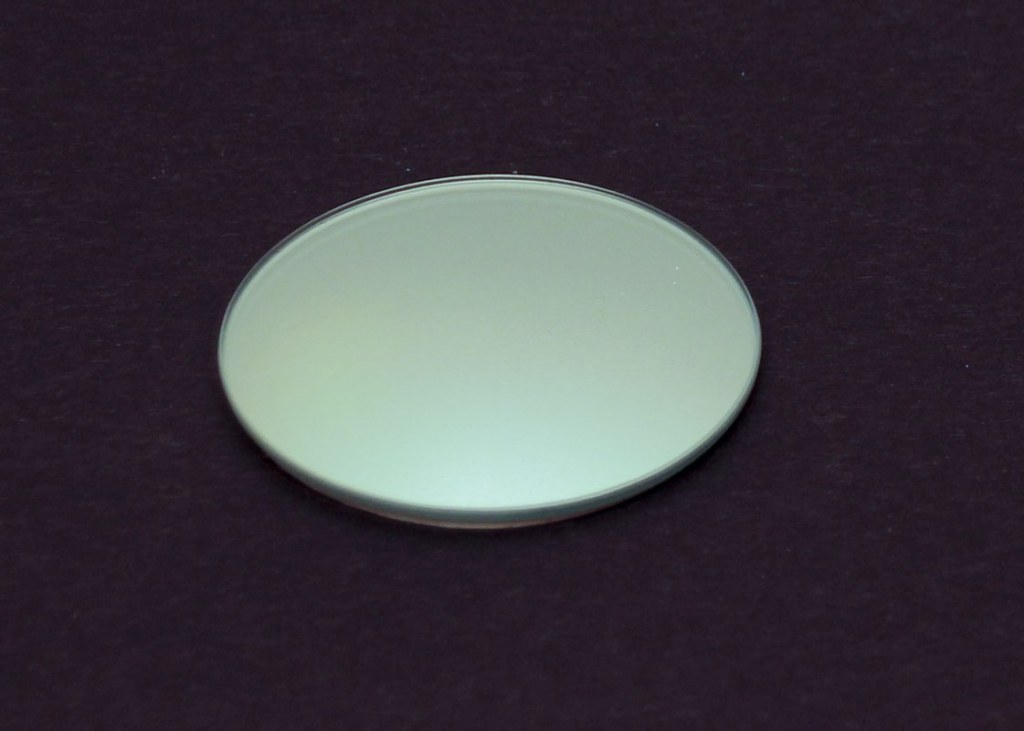

DeflectoZ Results on Curved Mirror

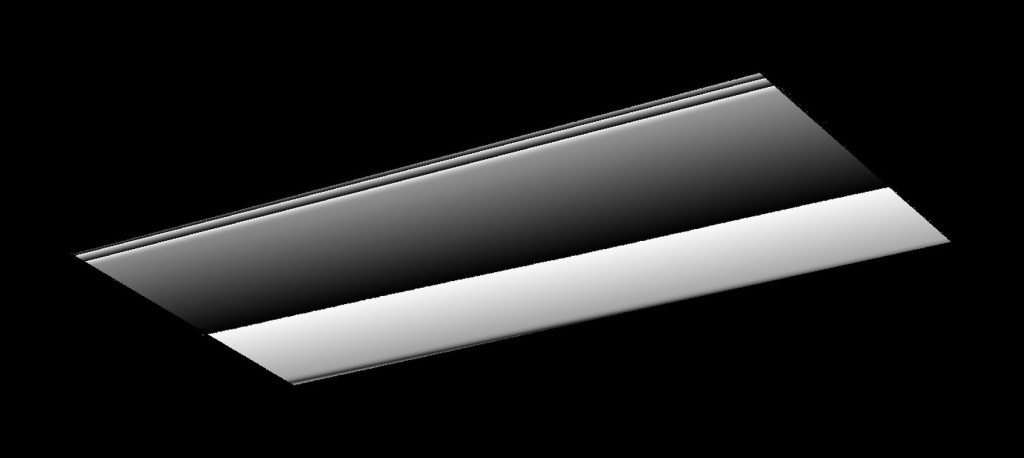

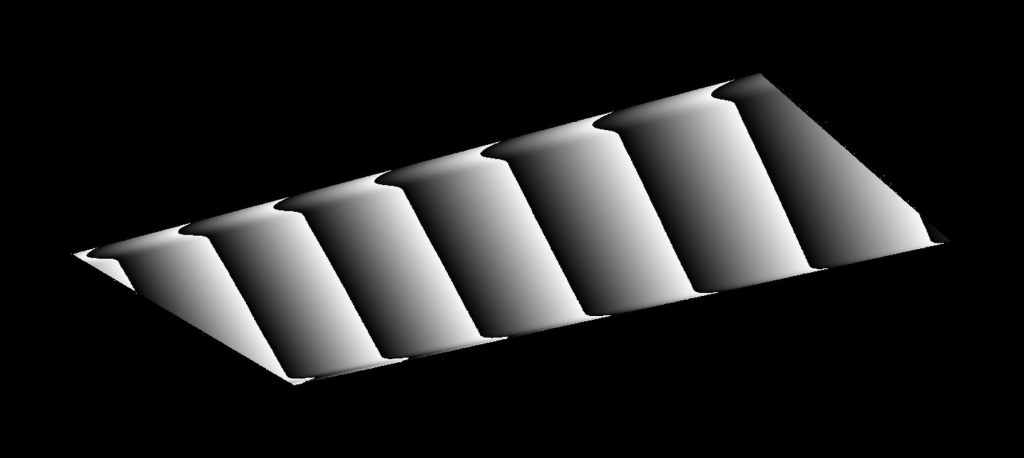

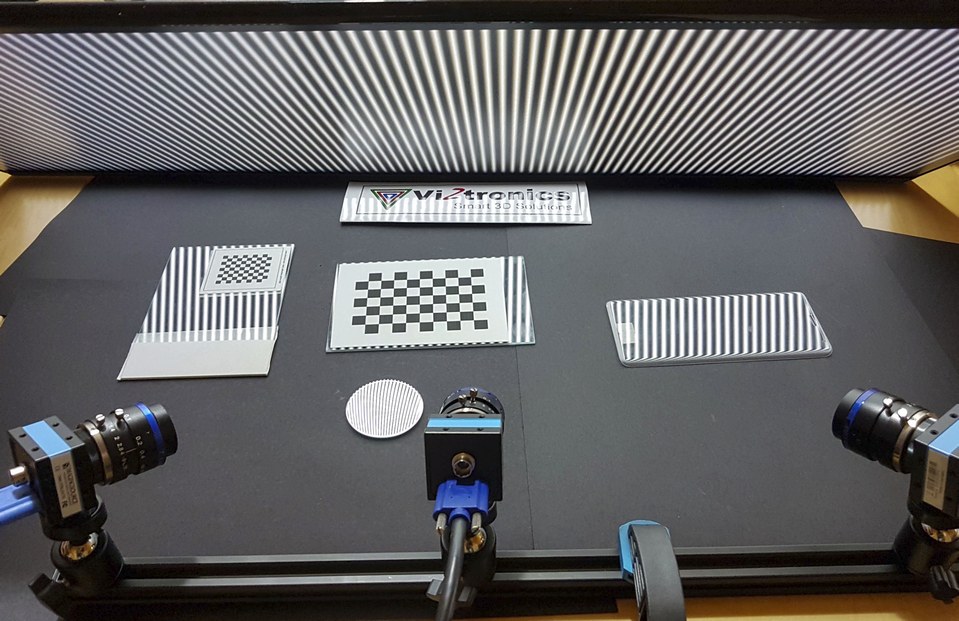

DeflectoZ – Applied to Orthopedics Implant Bin Picking

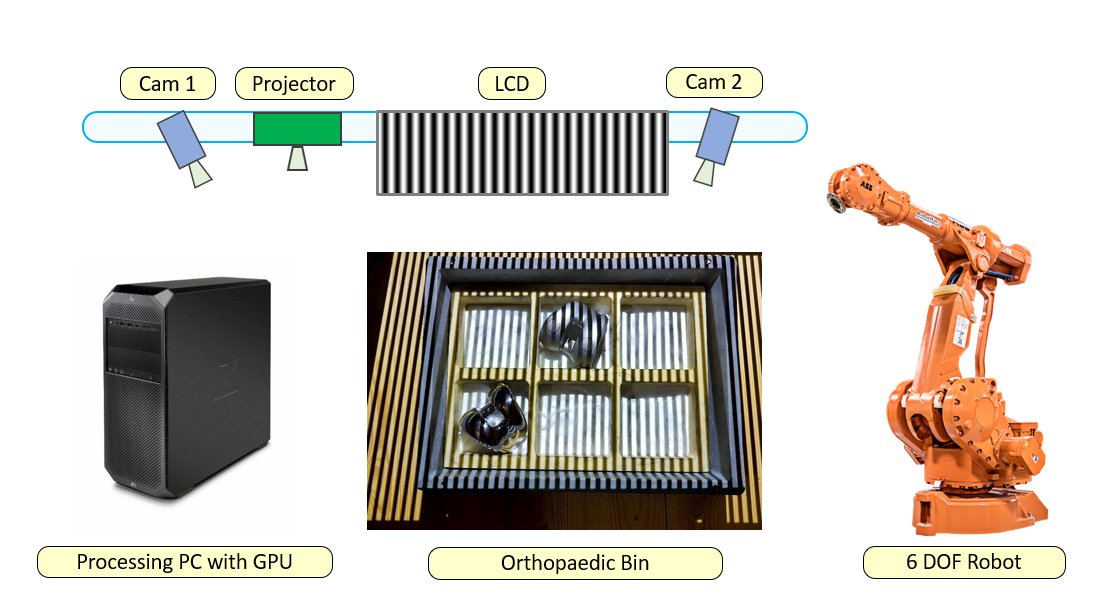

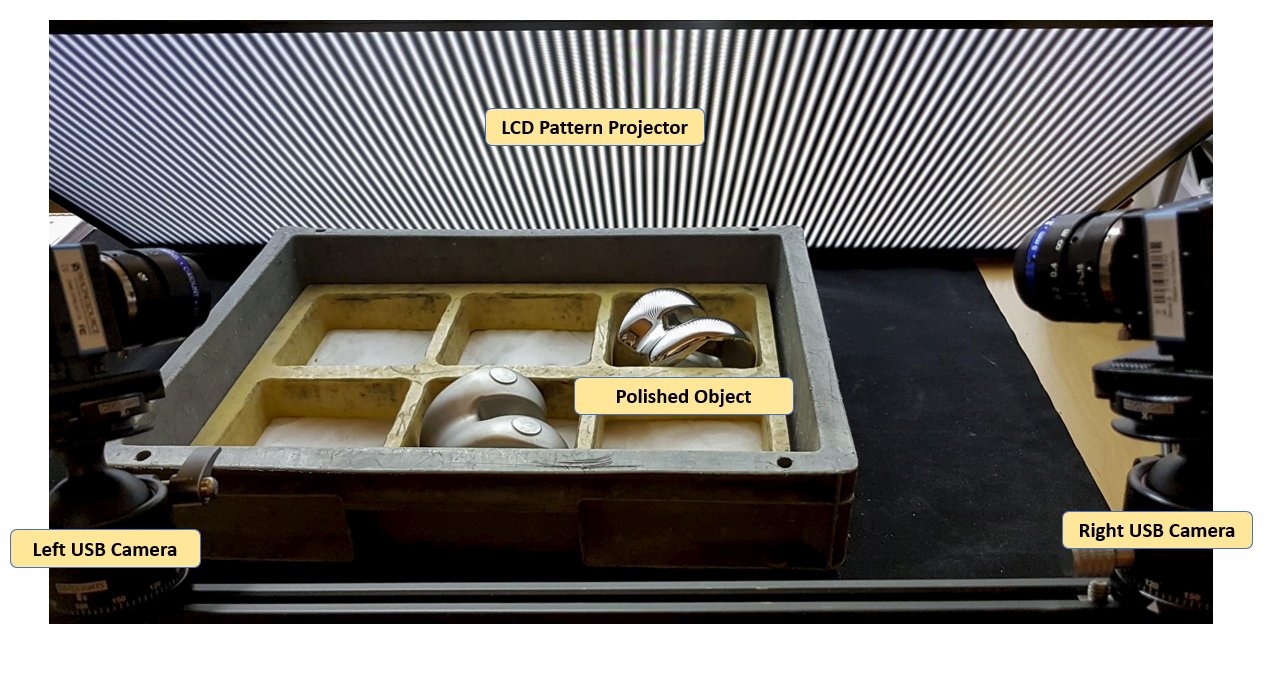

DeflectoZ setup for bin picking of Orthopedics Implants

DeflectoZ setup with two cameras and LCD screen.

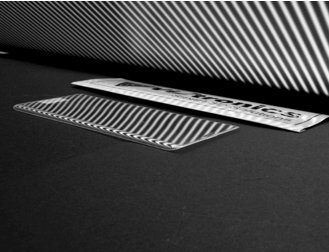

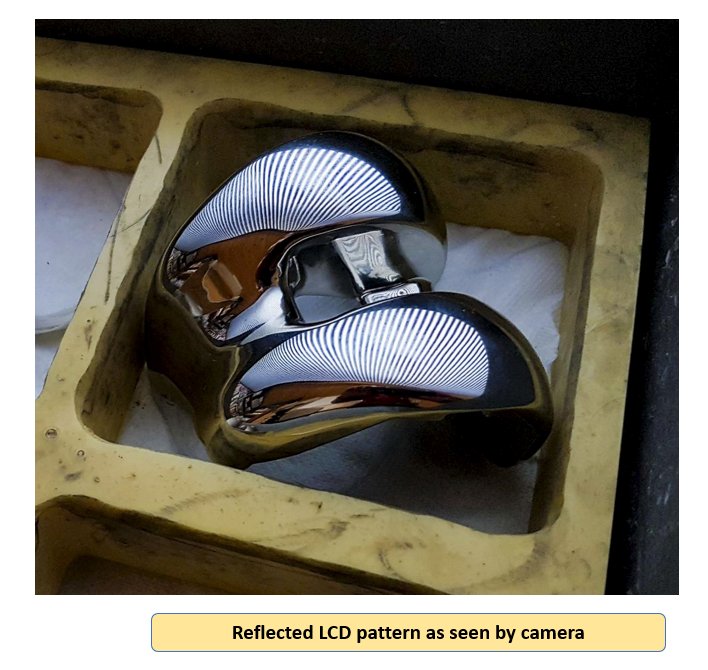

Reflected LCD pattern on an Orthopaedic Implant as seen by DeflectoZ.