Our Technology

SmartPhaze Technology

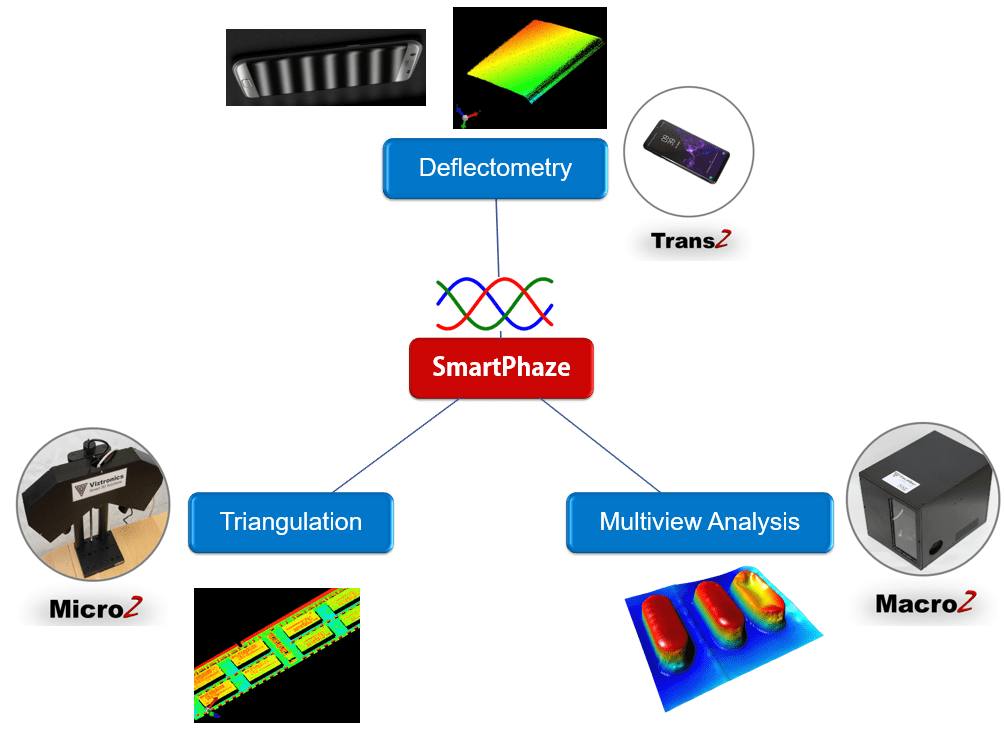

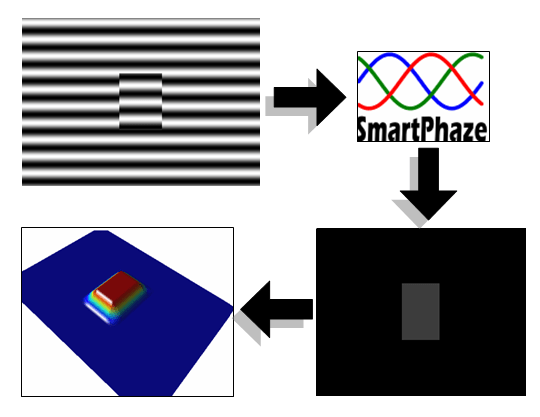

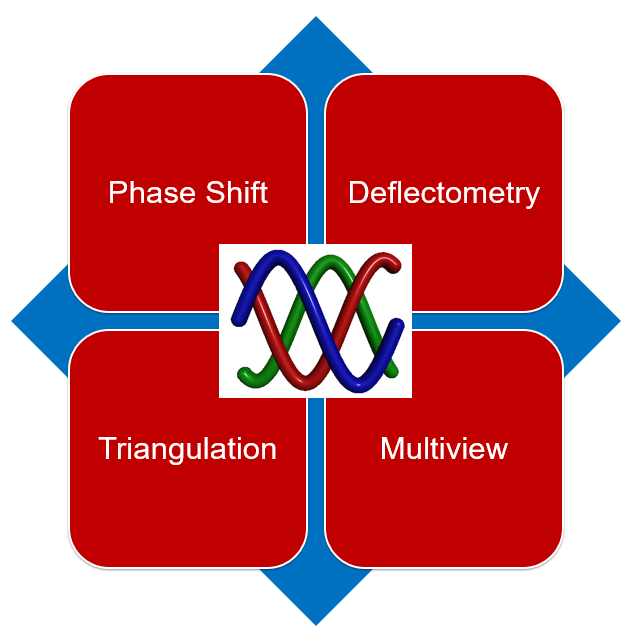

At Viztronics we have developed our own custom software solution to scan and analyse 3D images. We call it SmartPhaze Technology. This highly-differentiated technology is at the core of everything we do and allows us to provide reliable 3D inspection for our customers.

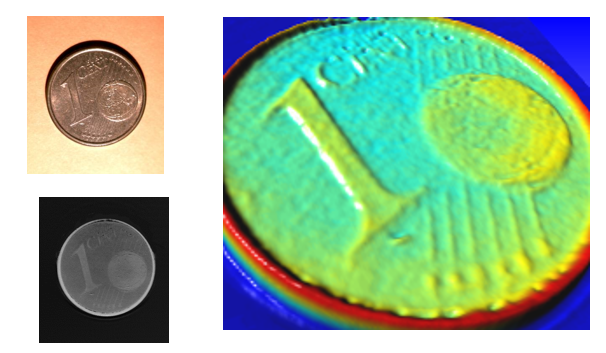

Viztronics’ sensors, combined with this software enable high-resolution 3D imaging of micro and macro scale objects including transparent glass and shiny metallic materials.

The Advantages of SmartPhaze

There are many advantages of SmartPhaze over competing technologies. Below is a list of some of it’s key advantages:

- Proprietary Multiphase projection and Multiview image analysis

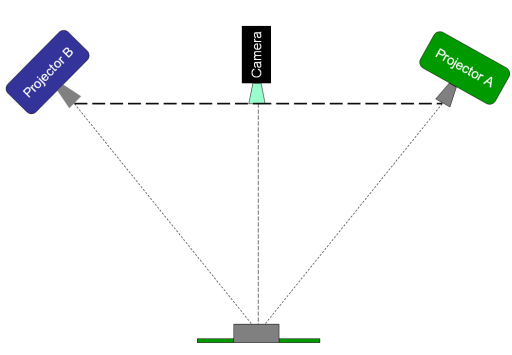

- Support Triangulation for diffuse 3D objects

- Supports Deflectometry for transparent and metallic objects

- Speckle proof and eye safe

- High resolution per pixel 3D data upto 30 Mega pixel

- HDR for specular and dark areas.

- Not affected by projector de-focus

- 2D and 3D image in one acquisition cycle

- Ability to tradeoff acquisition speed and 3D resolution/quality

- Optimized for 64-bit windows with C++ and .Net API

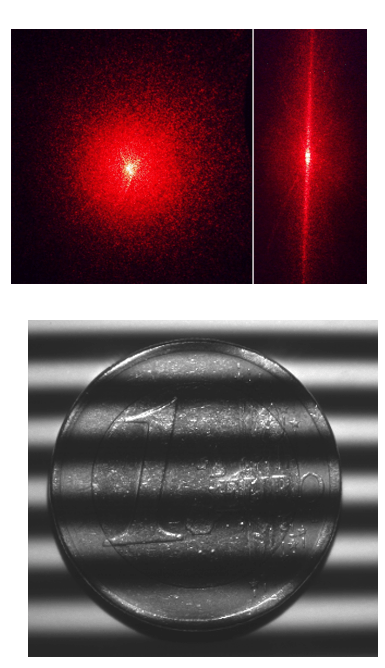

SmartPhaze Vs. Laser Triangulation

Many businesses still use laser triangulation for 3D inspection. However there are distinct distadvatages to this commonplace technology that SmartPhaze does noy suffer from.

Laser triangulation is impacted by speckle:

- Speckle limits 3D resolution.

- Industrial parts suffer most due to metallic finish.

- High-resolution cameras cannot help improve 3D quality.

SmartPhaze uses white light and sinusoidal patterns:

- Per-pixel high-quality 3D data.

- Supports camera up to 30 Megapixel.

- Eye-safe and speckle proof.

High-Res, High Range & HDR

SmartPhaze delivers 3D imaging which is high-resolution, high-range and HDR.

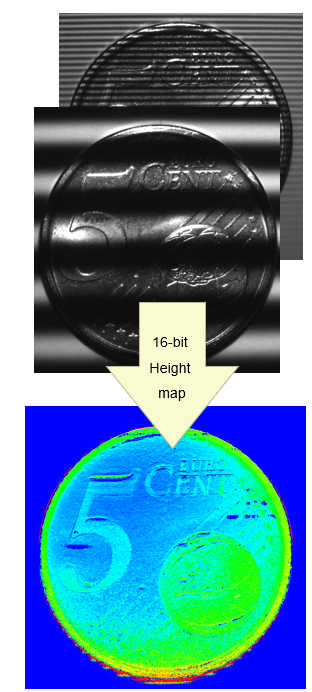

Patent-pending multiphase fusion:

- SmartPhaze fuse multiple phase images

- It generates 16-bit heightmap with:

- High resolution of finest pattern

- High range of coarser pattern

- Micron level resolution for cm range of 3D measurement

- Per-pixel HDR both for 2D and 3D

- Combine multiple exposures transparently

- High-quality data for specular and shiny areas

- High-quality data for dark areas

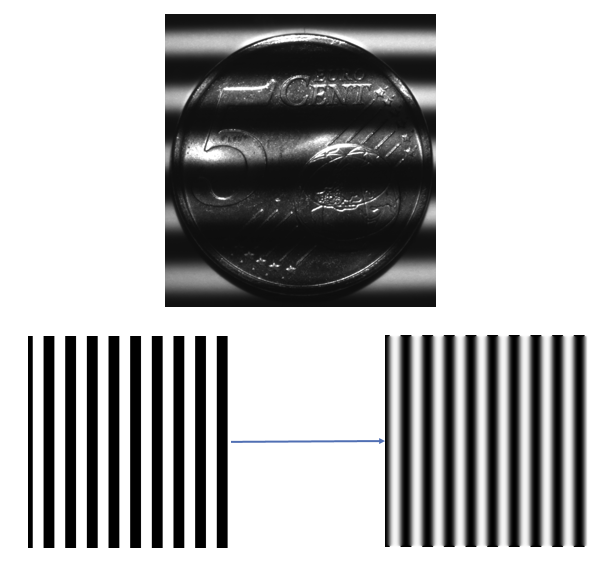

Resistant to Pattern Defocus

SmartPhaze is resistant to pattern defocus.

Compared to Binary patterns:

- Projector defocus doesn’t affect phase shift

- Sub-pixel resolution for 24MP camera with a SVGA projector

Deflectometry cannot focus on Object and pattern screen at the same time:

- Binary pattern cannot work for Deflectometry for 3D sensing of transparent and metallic objects

- Phase shift is the only option that works well for Deflectometry

2D Colour & 3D Point Cloud in One

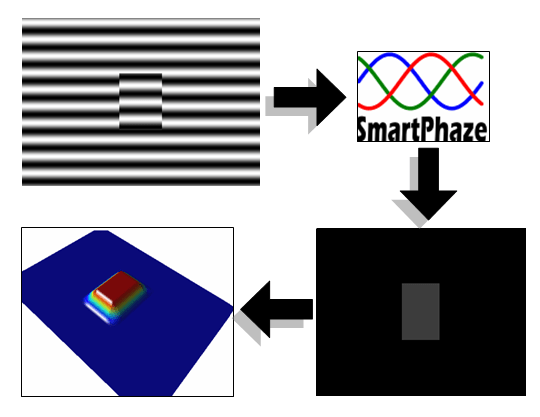

SmartPhaze given the following outputs after one sequence analysis:

- 3D point cloud with per pixel micron-level accuracy

- Per-pixel confidence measure

- 2D image (mono/colour)

These outputs can be used for further downstream machine vision analysis and implement a reliable inspection regime

Speed Quality Trade-Off

SmartPhaze provides flexibility to tradeoff 3D data quality against speed:

- Excellent speed using a minimum of 3 phase images

- Sub-pixel resolution limited only by optical resolution of camera by taking multiple phase steps.

- For multiphase a sub set of patterns can be used if full height range is not required.

- This allows inline inspection without impacting 3D data density and quality

Optimised .NET / C++ SDK

SmartPhaze provides optimized library for:

- 64-bit, multicore processors

- C++ and .NET interfaces

- Optimized for SIMD and GPU through OpenCL

- Calibration, Verification and Measurement using Triangulation and Delfectometry

- Sample application and data

- Kick start your custom design for 3D measurement for diffuse, specular or transparent objects.